We are a team of people who happen to be engineers, machinists, welders, fabricators and people who love to create and innovate. We’ve done things that show our passion – building the first form, fill and seal “wine in a box” machines in the world, machining materials used in constructing nuclear submarines, creating parts used in the toughest aerospace applications and building the first mid-engine Corvette (winner of the GM Vehicle Design Award at SEMA!). Whether the equipment is submerged 1000 feet below sea level, flying 40,000 feet above in the sky, operating in New York’s Freedom Towers or located in your building’s mechanical room, our commitment to you and simple solutions are same – we are on your team.

Who We Are

How We Create Your Solutions

1. EQUIPMENT SELECTION

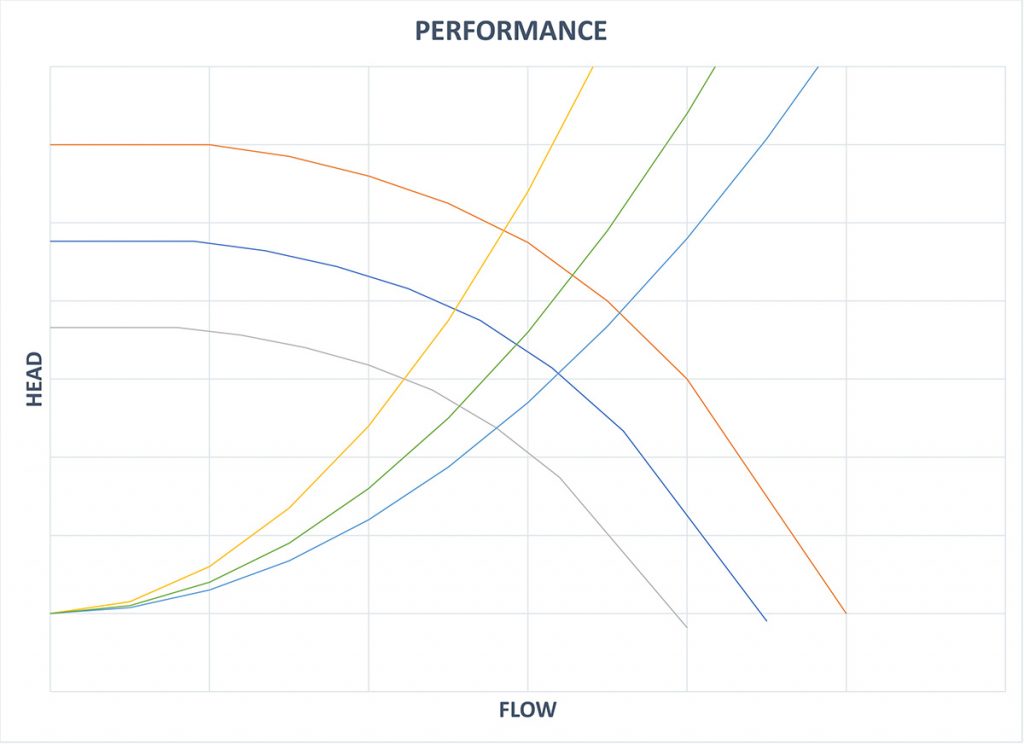

It all starts here – matching the system needs up to the equipment performance. For pump systems it means selecting a pump with a good curve (not flat), proper materials for the task, and a stellar efficiency. We are equipment agnostics, so we pick what is best for you and not just what we have to sell.

2. MATERIALS

Non omne quod nitet aurum est – All that Glitters is Not Gold

Our booster package headers and pump circuit piping are constructed using 304/316 stainless steel to ensure maximum longevity. While copper and bronze fittings can help lower first cost it comes at a price later.

3. COMPONENT SELECTION

Transducers – We use transducers with all stainless wetted components, protected diagrams, and 30 ms response rates. More expensive – HECK YEAH! Incredible Performance – ABSOLUTELY!

Threaded Ball Valves (2 inch and under) – Full port, 1000 WOG and all stainless – DON’T ACCEPT LESS. Within 1000 WOG rated valves there is a wide spectrum of wall thicknesses and depth of threads. We only use the best by selecting Ohio Valve. The higher weight and bigger size compared to their 1000 WOG competitors tells the story – GO RIGHT OR GO HOME!

Butterfly Valves (2 inch and greater) – Lug or grooved with stainless steel discs and bubble tight for your most demanding pressure applications.

Threaded 2 inch and under Check Valves: NPT inline, spring loaded check valves constructed of 300 series stainless steel with Buna-N O-Ring or PFTE seals and installed on the discharge side of each pump. Rated for VFD service and constructed to LAST!

Wafer – 2 inch and higher Check Valves: inline, center guided silent check valve with soft seats, straightening vanes and stainless steel disc and trim. Like the submarine service – quiet, flawless execution and always vigilant – TOP PERFORMANCE!

4. DESIGNING FOR THE USER!

Sizing – We size our headers and circuits to minimize pressure loss and maximize performance. Unlike some of our peers we keep the water velocities low which adds cost but it ensures the check valves have a LONG LIFE and the energy footprint of the package is MINIMAL.

Thermal Protection – Every booster unit is equipped with all stainless thermal purge valves to safeguard the pump.

Quick Disconnects – Our designs always focus on ensuring the equipment and components can be removed for service using the least amount of effort. This includes sanitary connections, oval flanges, grooved couplings and as a last resort flanged connections. SYSTEMS THAT ARE EASY TO MAINTAIN ARE WELL MAINTAINED!

Redundancy – We go the extra mile to ensure system redundancy. With our booster pump systems each pump is equipped with its own redundant transducer and the master control can switch between VFDs so in case of a failure the system can still operate! BETTER TO HAVE AND NOT NEED RATHER THAN NEED AND NOT HAVE!